NAO FLAME/DETONATION ARRESTOR Testing

Home ARRESTORS Products Rentals Services Tech Section Users

NAO does extensive testing on all of our

arrestors and also contract testing

for other arrestor & fire snuffing vendors

and clients with special requirements.

In our testing

area in Philadelphia, we test smaller units due to space and neighborhood

restrictions (noise and shockwave), but at our 150-acre Environmental Research and

Service Center

in Plantersville, Texas (40 miles - 65 km northwest of Houston), we can

conduct

large full-scale tests that will replicate your actual plant configurations (*see below)

and

duplicate your full range of flammable gas/ vapor conditions.

Examples of NAO Philadelphia Testing

Examples of NAO Texas Testing

Testing for Replacement of Defective Equipment

See the 3 photos and piping arrangement drawing

below for an example of FULL

SCALE HYDROGEN/AIR LIQUID SEAL DETONATION TESTING.

Hydrogen test for major drug company in Western Pennsylvania

after their Brand "X"

thermal oxidizer flame arrestor burners and

their Brand "X" detonation water seal drum failed.

The client told NAO; "the suppliers engineers were

very surprised with the failures, they

though the burners and the drum would

work" .

After the problem, the supplier did not or could not help.

The client requested NAO to supply replacement units.

Even with NAO experience with

hydrogen/oxygen for Three Mile Island nuclear plant, we

wanted to be positive since the

TMI (Three Mile Island) unit was only 3"

gas pipe VS 12" piping for the drug company

-- 16 times SCALE FACTOR --

thus we did FULL SCALE detonation testing.

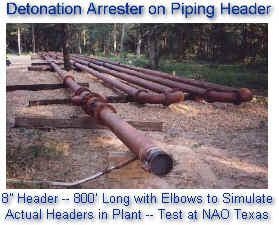

Another example of NAO Texas testing --- Exxon crude tank

*Actual Plant Piping Configurations

NAO

has available a large inventory of flanged piping, high pressure

NAO

has available a large inventory of flanged piping, high pressure

flexible

stainless steel hose and flanged fittings to setup your piping

configuration -- see drawing above of piping arrangement for

hydrogen

liquid seal testing.

NAO has pipe flanged sections from 2" to 36"

diameters with spool

lengths from 5' to 40' to make piping system to over 4000'

(nearly 1220 meters).

NAO also has flanged elbows, Y's, T's and manifolds to connect and simulate your piping layout.

These pipes, hoses & fittings are all PART OF NAO RENTAL FLARE & OXIDIZER FLEET.

Contact Jackie Mishinski at NAO Ext. 213 for Pricing & Full Details

Email ...... sales@nao.com

Phone ......

215-743-5300 or 800-523-3495 (All USA & Canada)

Fax ....... 215-743-3020

Home ARRESTORS Products Rentals Services Tech Section Users